In today's fast-paced industrial landscape, maximizing the efficiency and longevity of your machinery is paramount. One critical component that often gets overlooked is the auto filter. These devices play a crucial role in maintaining the performance of automotive and industrial systems, ensuring that contaminants are effectively removed from fluids and air. As machinery becomes increasingly sophisticated, understanding the importance of auto filters and implementing strategies for their optimal use can lead to significant improvements in operational efficiency and reduced maintenance costs.

This guide will explore the top strategies for selecting, maintaining, and optimizing auto filters to ensure your machinery runs at its best, ultimately leading to enhanced productivity and lifespan. Whether you are in manufacturing, transportation, or another sector, harnessing the power of auto filters is essential for any organization looking to thrive in a competitive environment.

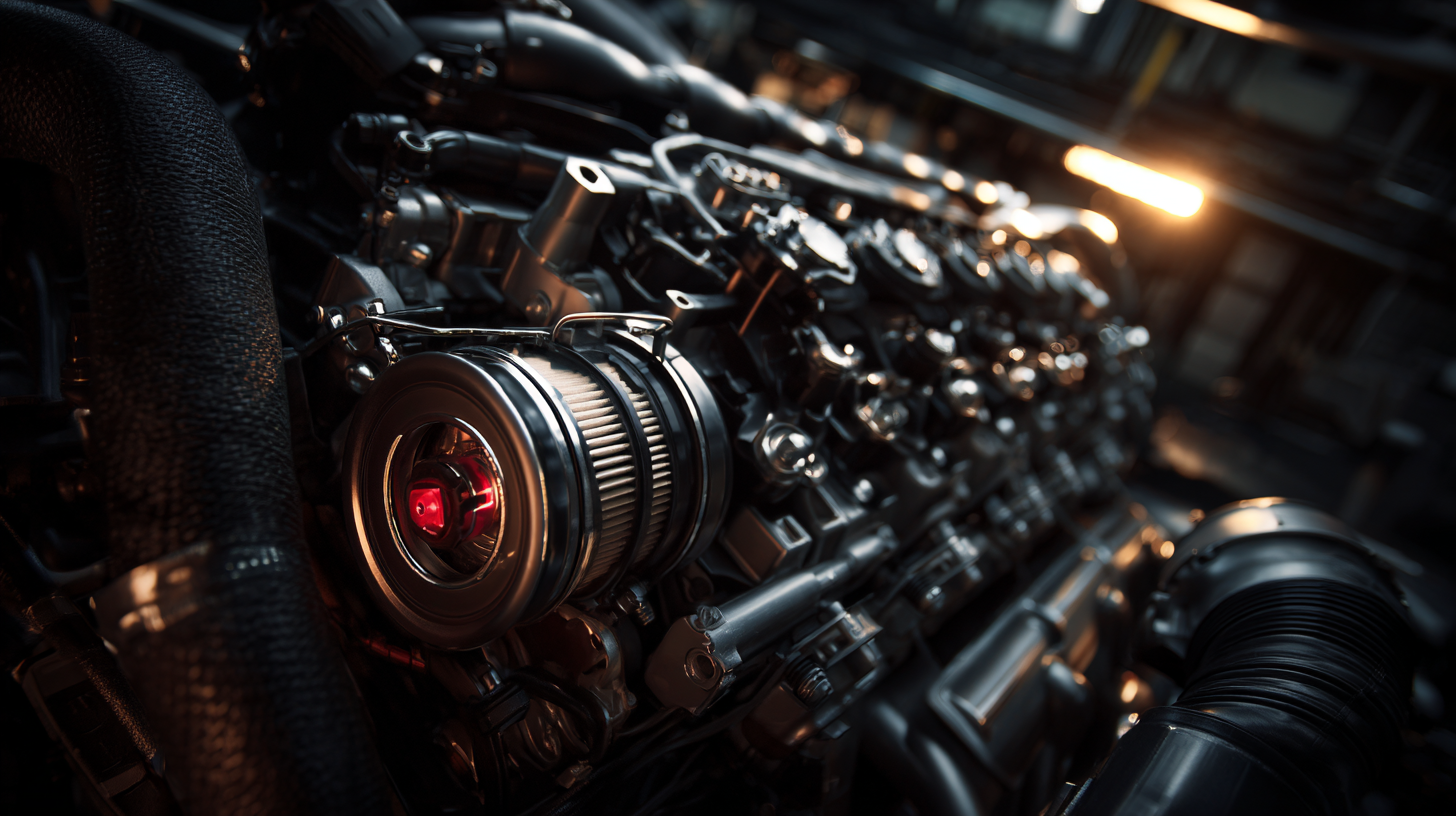

Auto filters play a crucial role in maintaining the efficiency and longevity of machinery. Understanding their types and functions is essential for anyone involved in equipment maintenance. Primarily, filters can be categorized into three main types: oil filters, air filters, and fuel filters. Each type is designed to remove specific contaminants from the corresponding fluid or air systems. For example, oil filters trap impurities that can cause engine wear, while air filters prevent dust and debris from entering the combustion chamber, ensuring optimal performance.

Auto filters play a crucial role in maintaining the efficiency and longevity of machinery. Understanding their types and functions is essential for anyone involved in equipment maintenance. Primarily, filters can be categorized into three main types: oil filters, air filters, and fuel filters. Each type is designed to remove specific contaminants from the corresponding fluid or air systems. For example, oil filters trap impurities that can cause engine wear, while air filters prevent dust and debris from entering the combustion chamber, ensuring optimal performance.

The functionality of auto filters is equally important to comprehend. They utilize various filtration methods, such as mechanical, chemical, and electrostatic filtration, to capture contaminants effectively. Mechanical filters, for instance, rely on a physical barrier, while chemical filters may use absorbents to remove impurities. Regular maintenance and timely replacement of these filters not only enhance the performance of your machinery but also prolong its lifespan, ultimately saving costs on repairs and replacements in the long run. By grasping the fundamentals of auto filters, you can make informed decisions that contribute to the overall efficiency of your equipment.

When considering the efficiency and lifespan of auto filters, several key factors come into play. First and foremost, the quality of the filter media significantly influences performance. According to a report by the Filtration Society, filters made from high-grade synthetic materials can achieve up to 99.9% efficiency in trapping contaminants, compared to only 85% for standard cellulose filters. This enhanced filtration capability not only ensures cleaner oil or air pathways but also means that the machinery operates under optimal conditions, extending its overall lifespan.

Another critical aspect is the filter design itself. Industry studies indicate that filters incorporating pleated designs allow for a larger surface area, resulting in improved dirt-holding capacity and reduced pressure drop—even during heavy use. A study from the International Journal of Fluid Engineering suggests that well-designed filters can double their lifespan, pushing it beyond the typical replacement intervals. Thus, selecting filters with superior design and materials is vital for maintaining efficient machinery and minimizing operational costs over time.

When it comes to ensuring the longevity and efficiency of your machinery, selecting the right auto filter is a crucial step. The first guideline is to understand the specific requirements of your equipment. Different machines operate under varying conditions, which means they require filters tailored to those unique environments. Research the type of contaminants your machinery typically encounters, whether they be dirt, water, or particulates, and ensure that the filter you choose is designed to handle those specific challenges.

Next, consider the filter's specifications, including its micron rating and flow rate. A filter with a lower micron rating will capture finer particles, which is essential for sensitive equipment, while a higher flow rate is necessary for machinery that requires rapid fluid movement. Additionally, examine the material and construction of the filter. High-quality materials can improve durability and reduce the frequency of replacements, ultimately saving costs in the long run. By following these steps and choosing the correct auto filter, you can significantly enhance the performance and lifespan of your machinery, ensuring smooth operations for years to come.

Maintaining and replacing auto filters is critical for ensuring optimal performance in machinery, as clogged filters can lead to decreased efficiency and increased operational costs. According to a report by the Automotive Maintenance and Repair Association (AMRA), approximately 20% of all engine problems are linked to poor filtration. Regularly inspecting and replacing auto filters can not only save money in the long run but also prolong the life of machinery. It is recommended that air filters be replaced every 12,000 to 15,000 miles, while oil filters should be changed per the manufacturer's specifications, typically every 5,000 to 7,500 miles.

Best practices for maintaining auto filters include adhering to scheduled maintenance checks, using quality filters that meet industry standards, and considering the operating environment of your machinery. For example, the Society of Automotive Engineers (SAE) suggests that filters in harsher conditions—such as those involved in construction or mining—may require more frequent replacements to prevent dirt and debris from affecting performance. By being proactive about filter maintenance and replacements, machinery operators can enhance efficiency, reduce downtime, and ultimately improve the overall lifespan and reliability of their systems.

When it comes to maximizing the efficiency and longevity of your machinery, using auto filters correctly is crucial. One of the most common mistakes people make is neglecting maintenance schedules. Failing to replace or clean filters at regular intervals can lead to decreased performance and potential damage to machinery components. It's essential to follow the manufacturer's recommendations regarding filter servicing to ensure optimal operation.

Another error often seen is using the wrong type of filter for specific machinery. Selecting filters that aren't compatible with the equipment can result in inadequate filtration, leading to contaminants entering critical areas. Always verify that the filter is designed for your machine’s specifications, as even minor discrepancies can have significant consequences. By avoiding these pitfalls and prioritizing proper filter care, you can enhance the reliability and longevity of your equipment.